The supply chain requires efficiency for optimised results, and in 2017 technology is a big step in optimising this efficiency. New technologies, in particular, have the capacity of being utilised for innovations and progress in the supply chain.

In 2017, some of these technologies are expected to provide a streamlined process from the first to the last step of the supply chain.

The Internet of Things (IoT)

Digital economy is based on digital computing and derived technologies, and the Internet of Things is a big component for its functioning. According to Gartner, the six billion connected devices we have now can be around 21 billion by 2020. Relying on sensors, their falling price is propelling their integration in the supply chain.

While most companies still haven’t fully used the Internet of Things to its full capacity, this is expected to change in 2017. This use of data will allow for businesses to utilise it in a harmonious manner, analysing it and delivering it with a new speed.

Robotics and Augmented Reality

With an expected 10% growth in the next 10 years, robotics can be expected to increase their role in manufacturing and handle up to 40% of its processes. The efficient use of robotics in manufacturing for some industries could lead to a rise in jobs, as robotics simply induce a re-skilling of the workforce and change in jobs instead of replacing them.

The acceleration of production will also be possible through augmented reality, as components such as smart glasses can transform both the field service and the training. With lower labour costs and errors throughout all manufacturing processes, the impact on production speed will easily be seen in a positive way.

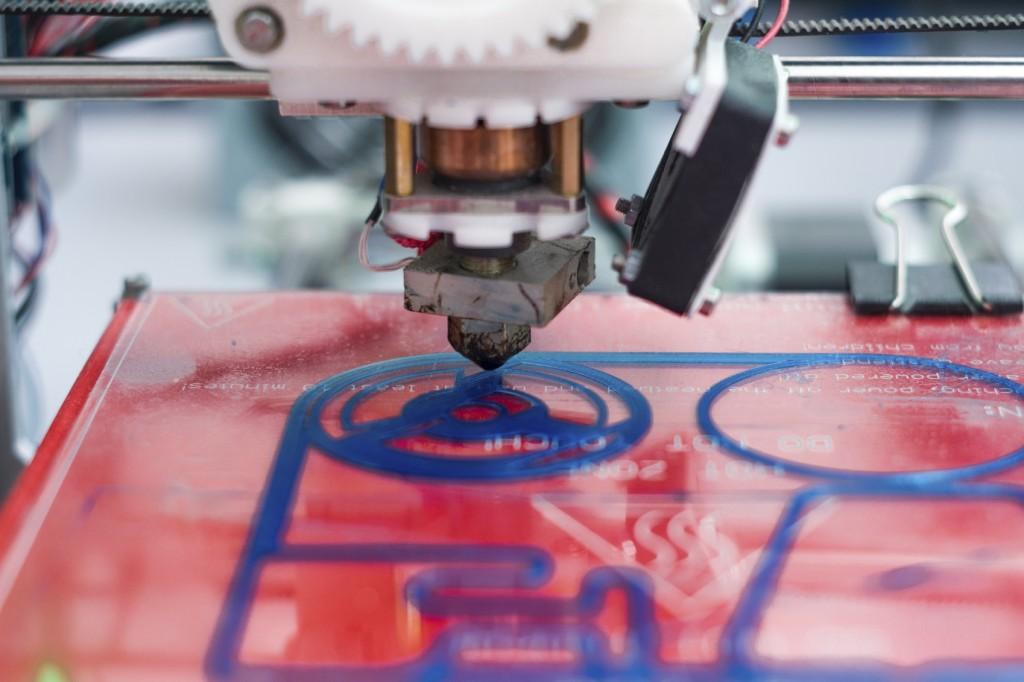

3D Printing

The rise of the use of 3D printing has been seen in the past years, but 2017 will be the year in which 3D printing enters the mainstream market. With sales of 3D printers doubling in 2016, it’s expected that the number will be around 6.7 million in 2020. With approximately 42% relying on it for mass production in the next years, inventory and logistics will undergo a big change.

Parts and components will be stored in software and not on shelves with the rise of 3D printing, allowing for inventory to be digital and therefore optimised. Additive manufacturing, utilised by approximately 7% of businesses, will also play a big part in guaranteeing an optimised shipping process in 2017.

Rise of Cybersecurity

The increase of use of new technologies and of the Internet of Things will require a rise in cybersecurity for all industries and businesses that rely on these new technologies. Devices that are interconnected with the Internet of Things can easily be hacked, compromising companies and their services.

There will be a bigger necessity for new cybersecurity technology, particularly one that allows for blockchain, which is a decentralised database of constantly growing records, also known as blocks. These blocks have a timestamp and a link to the previous block, which doesn’t let them be duplicated. Bitcoin utilises these blocks as core components, and the supply chain will see it be used for the optimisation of its processes.

Barcoding inventory systems are vital for the modern supply chain, and here at GSM Barcoding we provide a wide variety of services that are sure to fit your needs.

To learn more about this and the technologies that can help you stand apart from the competition, increase your productivity and improve your warehousing, download the full, free report below: