Tracking software has revolutionised the way businesses perform their operations. The demand for products across every sector has steadily increased over time, and new production processes and technologies have been introduced to keep up. The ever growing supply of inventory owned by businesses demand more sophisticated means of tracking and storing these assets.

Whilst currently there is a multitude of sophisticated and advanced digital technology designed for asset tracking, this was not always the case. Let’s take a look back at some of the first types of asset tracking systems and how they have developed into the systems we use today.

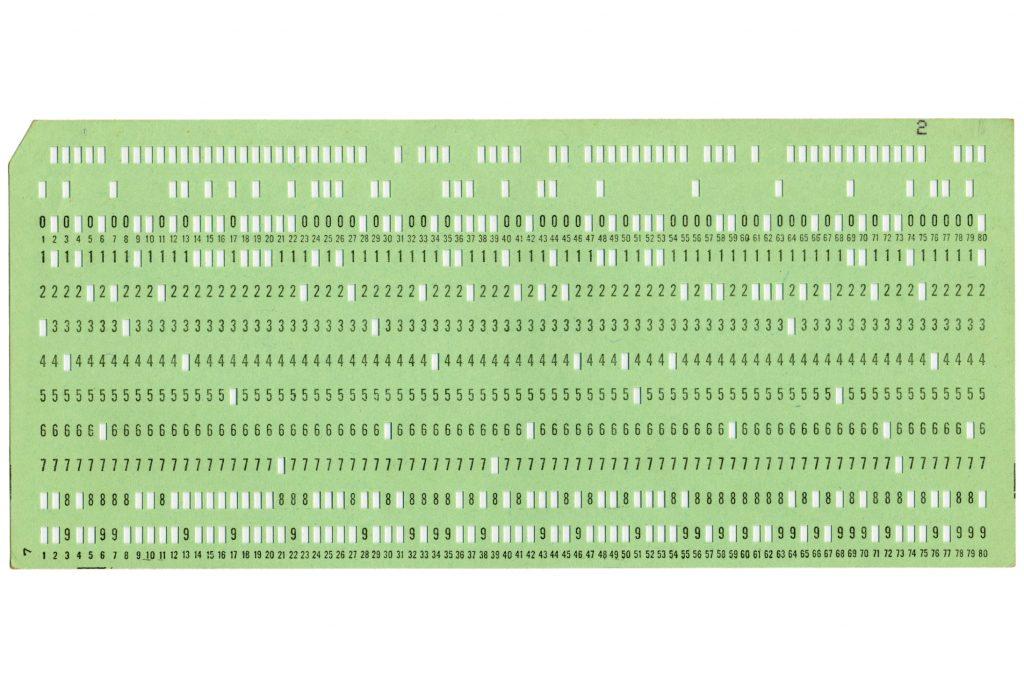

Machine-Readable Punch Cards

One of the earliest forms of asset tracking – if we forgo simply counting the number of items in stock and making a note of that number – came in the 1800s with the invention of the machine-readable punch card. These were paper cards containing several punched or perforated holes that were done by hand or with a machine to represent data. It was an early method of data storage used with early computers.

Punch card readers were used as input devices to take data from the card and send it to the computer. Whilst this was no doubt revolutionary at the time, there were a lot of drawbacks to this kind of slow, manual system.

Barcodes and Spreadsheets

On June 26th 1974, in a small town in Ohio, the first item was marked with the Universal Product Code (UPC) and scanned at the checkout. The barcode had been a work-in-progress since 1949, when Joe Woodland had an epiphany about how he could come up with a solution to the supermarket dilemma of wanting to get shoppers through the checkout process more quickly. The decades that followed saw a crude prototype of a laser, a bull’s-eye barcode, a committee trying to decide on a universal identification code, and today’s technology giant IBM throwing their hat into the ring by innovating the well-known rectangular barcode we know today.

Like so many inventions, the UPC was not an immediate success. It took off in the grocery and retail business in the 1980s and eventually began to transform the manufacturing industry, which benefitted immensely from instant identification. This, combined with the introduction of personal computers and spreadsheet software, made updated inventory counts much easier and more streamlined. However, it didn’t yet offer all the other helpful features that we use today, such as historical tracking. Spreadsheets lacked real-time tracking capabilities and the functionality of automatically updating asset records. Clearly an asset tracking system was called for.

Wi-Fi

In the 2000s, peaking around 2005, Wi-fi was attached to asset tracking equipment as a means of tracking their locations. The tags would ‘chirp’ every few seconds to signal their location, and this information was recorded in a database. However, this use of wi-fi had a number of limitations and fell out of popular use.

Firstly, the battery life was very limited, needing replacing every few months. Coupled with the fact that it would take a significantly long time to track down assets when their tag batteries had failed, this system became a serious problem. The costs of this system were also high; each asset needed its own tag, a database needed to be able to identify which tag was on which asset, and the system needed to understand the floorplans and tracking locations as well as integrating with existing inventory management software.

RFID

Sometime later, manual inventory tracking was replaced by scanners and Radio Frequency Identification (RFID), and this technology gave way to advanced tracking. RFID barcodes can store more information about a product, and they allow for automatically tracked assets, gathering point-in-time information on items as they work their way through the downstream supply chain process.

Customisation

Possibly the most innovative development to improve asset tracking for businesses has been the ability to completely customise tracking software for their asset labels. Everything from stock control solutions, asset tracking, barcode label printing, and even mobile solutions have been innovated to streamline the way companies control and monitor their assets.

Tracking software has come a long way; it has never been simpler to keep track of every single one of your assets. You can save time, money and productivity with an asset tracking system from GSM Barcoding.