The automotive industry is probably not the first industry that comes to mind when you think of barcodes. However, barcode technology has helped to revolutionise this industry by providing fast and accurate inventory and shipping information to pass among trading partners throughout the supply chain.

Barcoding in the automotive industry presents unique challenges. The labels need to be able to withstand mechanical, chemical and climatic exposure due to the nature of their use within this industry. The use of labels in the automotive industry includes supply chain labels, under bonnet labels, variable data labels, VIN labels and engine parts labels. VIN labels include world automotive manufacturer identification, type of restraint system, manufacturer’s specifications, line series and body type, engine type, a check digit, year of model, where the vehicle was assembled and the production sequence number.

The complex nature of the automotive industry makes barcoding an important aspect of the production and distribution. With all that information stored on a label that can be scanned and retrieved, barcoding is practically essential to such a huge industry.

The First Barcodes

Did you know that the first ever automatic identification technology was used for vehicles? Railroad cars to be precise. In the late 1960s, railroads in North America began searching for a system that would allow them to automatically identify railcars and other stock. Several different systems were developed and put through extensive field tests. At the Pennsylvania Railroad, an undergraduate at MIT developed a system called KarTrak, which used blue and red reflective stripes that were attached to the side of cars and had encoded digits. This system was the one that was chosen to be used as standard.

Starting in 1967, all railcar owners were required to install labels on their cars. By 1975, 90% of all railcars were labelled, and the read rate was about 80%. This non-perfect read rate eventually led to KarTrak’s demise, as the reason for the failure to read certain labels was due to the accumulation of dirt. Regulations were instituted for label inspections to take place every two years to counter this, but the maintenance program never gained sufficient compliance. The read rate failed to improve, and KarTrak was abandoned in 1977. The railroad industry did not seek out another system to identify railcars until the mid-1980s.

Odette & GTL Automotive Labels

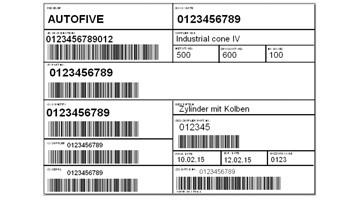

At GSM Barcoding, we supply, design and print labels in accordance with the Odette pan-European collaboration and services platform, which sets label standards across the automotive network.

Typically designed to standard label sizes and placed on containers and packaging, the Odette label is used by manufacturers to accurately identify goods via barcodes and relate the physical arrival of the goods to the ODETTE Despatch Advice message. We can provide Odette Standard labels to your requirements:

- Permanent or peelable adhesive labels

- Paper or synthetic substrate

- Supplied plain or printed bespoke

- Call-off volume contracts

GSM Barcoding can assist you with your Odette labels, GTL (global transport labels) which cover Europe, US and Japanese markets and provide label services such as high-volume call-offs, so you receive your labels when and where you need them.

Automotive Under Bonnet Labels

We can create permanent, durable adhesive labels that are ideal for applying to metal surfaces and suitable for automotive applications such as engines, where they would be subjected to significant fluctuations in temperature. Our labels are designed to maintain their integrity and be resistance to chemicals, solvents and oil-based products.

Our products are designed to meet industry standards and the requirements of OEM or Tier 1. We custom design them to be suitable for harsh environments and chemical exposure. GSM Barcoding use a full range of materials and adhesives according to your particular needs. Our specialist printing techniques can produce high definition digital printing or printing onto plastic and metal labels.

Decal Automotive Labels

We can supply labels made to any size and shape which display legible and intact safety information for the vehicle’s entire life. Our labels are manufactured from a high-quality synthetic material which is scratch/tear resistance, waterproof and highly durable. The durability of our automotive decals and warning signs meets industry standards and will not fade or rub off, and they come in a range of colours, sizes and materials.