Since the first barcode scan more than 40 years ago, identification and traceability technologies have evolved into one of the most essential foundations of modern business operations. Today, those advances are continuing in label printing, RFID, NFC and AI scanning, which have reshaped how organisations track assets, manage supply chains, and interact with customers.

This modern guide from GSM Barcoding will help you understand how today’s labelling is changing for your industry—and how to choose the right label solution for a data-driven world.

Why Label Choice Matters More Than Ever

Labelling has evolved beyond simple product identification. In various sectors such as retail, healthcare, logistics, manufacturing, and field services, operations now depend on labels to enhance accuracy, supply chain resilience, automation, and regulatory compliance. Choosing the appropriate symbology, design and composition is essential if you want improved accuracy & efficiency, to boost productivity, reduce waste, and improve traceability. All factors that directly impact performance across your organisation.

Operations Managers are increasingly confronted with industry pressures, including the demand for shorter lead times and greater complexity in supply chains. These challenges have driven innovation in labelling, resulting in the introduction of QR codes, smart labels, traceable packaging, and more durable label materials. For label suppliers like GSM Barcoding, emerging technologies and digital printing have made these innovations accessible to a broader market, enabling shorter production runs, variable data printing, and quicker turnaround times.

Understanding Modern Barcode Technology

A barcode symbology defines how data is encoded and read, making your choice crucial for successful workflow automation. As of 2026, both 1D and 2D formats are affordable and popular, but their impact has dramatically evolved.

New Developments in Barcoding

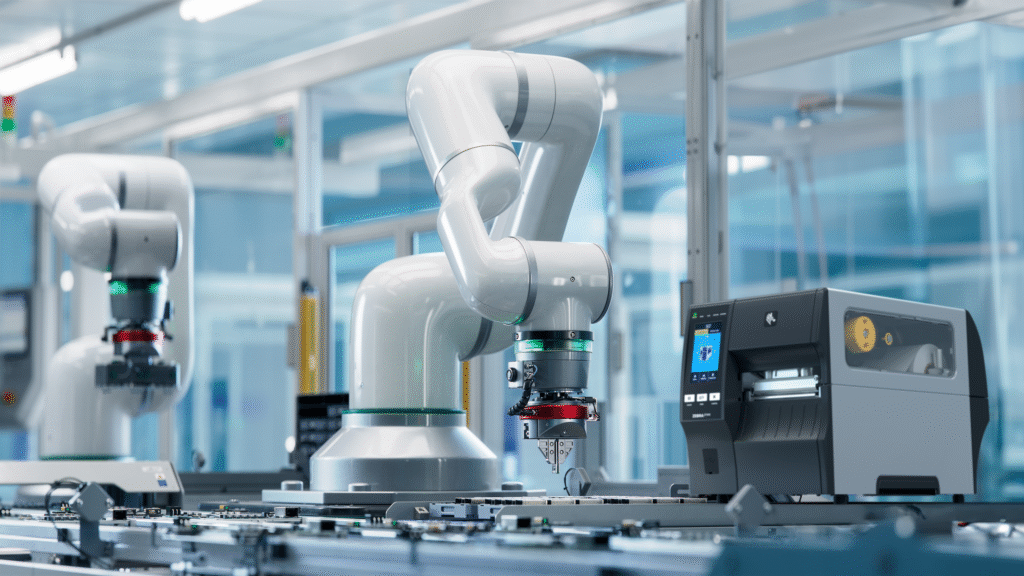

Emerging AI-powered barcode recognition is an exciting development being adopted by leading scanner manufacturers like Zebra. This technology can effectively read damaged, obscured, or poor-quality codes – quickly and accurately. Its implementation in manufacturing and logistics settings has significantly improved scan success rates, particularly in fast-paced production workflows and sortation systems.

Mobile scanning is now a common practice in operations, with workers using standard smartphone cameras alongside enterprise-grade decoding apps. This advancement has made high-quality industrial scanning accessible in environments where it was previously unavailable, such as field operations. Although smartphones may have limitations in industrial applications, their impact on service delivery is increasingly notable.

In addition, the latest advancements in 2D barcodes and the GS1 Digital Link offer innovative digital traceability & look up functions for operations. These developments allow packaging to connect directly to online product data, enabling authenticity checks, sustainability information, and enhanced consumer engagement. This technology is enhancing supply chain transparency & consumer interaction across various industries, reducing fraud and improving consumer safety.

Common Symbology for Today’s Industrial Workflows

The variety and innovation in coding symbology have significantly increased, with certain codes being better suited for specific applications and industries. System designers should choose codes carefully, as this choice can impact both data capture and the workflow. It is advisable to consult with GSM Barcoding when specifying code labels. Some of the most common codes used for labels include:

Code 128

One of the most versatile one-dimensional barcode symbologies capable of encoding alphanumeric data, encompassing all 128 ASCII characters, within a compact format. This type of barcode is frequently utilised in logistics labelling and packaging due to its dense design, which makes it particularly suitable for applications where space is at a premium.

Code 39

A variable-length 1D barcode symbology developed to encode alphanumeric characters. It is commonly used in the automotive, manufacturing, and defence industries for inventory tracking and asset tagging. This coding system is particularly effective in environments where there is space for labelling, ensuring clear identification and tracking.

QR Codes & Data Matrix (2D)

QR codes have become increasingly popular and are now used in various sectors due to their accuracy and the ease of image capture they provide. They enhance interactivity for consumers and are commonly found in retail, events, packaging, and smart labels. Recent advancements have expanded their applications to include high-capacity data encoding, which improves data capture capabilities. Additionally, the integration of the GS1 Digital Link further enhances their role in promoting transparency and traceability.

Smart Labels: RFID, NFC & IoT Integration

Smart labelling technology enhances traditional barcoding by incorporating a layer of digitisation, which enables more automated data capture, often without line-of-sight scanning, improving tracking throughout the supply chain. These smart labels are expanding beyond narrow applications as confidence grows, their costs decrease, and they are now becoming common across various sectors, including retail, logistics, manufacturing, healthcare, and field services. Smart labels provide valuable data for more complex workflows and facilitate better interactions for both consumers and supply chain professionals.

RFID Labels

The original smart label RFID has achieved rapid expansion in recent years as the price for passive tags has decreased and the technology has improved. RFID (Radio Frequency Identification) technology is largely driven by its ability to enhance operational efficiency, with reads rather than scans being conducted faster. RFID offers significant advantages, including real-time inventory visibility for items with active tags, automated data capture via portals and gates, the ability to read multiple tags simultaneously, and the capability to read labels without needing a direct line of sight.

Operations can choose between passive tags and active tags depending on whether they need to track items in real-time and their budget. Companies that adopt RFID labels often experience a strong return on investment, as RFID helps reduce shrinkage, improve accuracy, and expedite supply chain operations.

Industry applications include:

- Automated warehouse tracking

- Retail stock‑level monitoring

- Encrypted RFID tags protecting pharmaceutical supply chains.

- Tags can be rewritten to improve tracking for WIP.

If you would like a FREE RFID consultation, speak to one of our team, and we will be happy to advise what is the best label technology for your operations.

NFC Labels

Near Field Communication (NFC ) media are labels or tags that add a digital layer to your labels using embedded chips that enable short-range wireless communication to devices like smartphones. NFC labels add interactive content to your label, expanding the information that you can provide, such as product information and connectivity to inventory management and warehouse automation data.

Application uses of NFC labels include:

- Product authentication

- Interactive marketing

- Identity & access control

- Inventory & Asset management

NFC labels foster trust by allowing customers to verify the authenticity of their purchases, while also offering interactivity. This makes them a popular choice for premium and regulated products such as wines, spirits, pharmaceuticals, and electronics. Businesses that wish to adopt NFC tags enable greater communication with their customers whilst keeping their material label design minimalist.

IoT‑Enabled Labels

The integration of labels with Internet of Things (IoT) sensors for data capture represents a significant advancement in the industry, offering real-time updates on environmental conditions and variables that may impact machines and items in transit. Labels are generally classified based on their communication methods and power sources. Passive tags, such as NFC or RFID, derive their energy from the reader’s signal, while typical IoT labels use Bluetooth Low Energy (BLE) technology and may also incorporate GPS or semi-passive tags. IoT labels enable you to:

- Automatically log events

- Remotely monitor conditions

- Real-time supply chain visibility

- Conduct real-time location (RTL) tracking

IoT‑connected barcodes/RFID tags are increasingly used in cold-chain distribution and environmental monitoring to monitor the condition of stock in transit, improving the quality and accountability of items in the supply chain. IoT labels are also used for assets such as machinery and plant, where the capture of live sensor data helps with day-to-day monitoring and maintenance, reducing costs and the risk of downtime.

Modern Labels Across Industries

Many industry sectors are experiencing significant improvements due to advances in barcoding labels. The primary benefits of compliance, accuracy, and speed are especially important in areas where high-volume processing is essential, and precision is crucial.

Laboratory & Healthcare Labels

In environments where precision is paramount, the importance of clear and accurate labels cannot be overstated—blurred or erroneous lab labels can lead to clinical delays, costly rework, and significant risks to patient safety.

Healthcare requires specialist label materials and adhesive solutions that are designed to withstand the rigorous testing, storage, and cleaning requirements typical in laboratory environments, while also demonstrating resistance to degradation. Code 128 and Data Matrix barcodes continue to be the popular choice in applications requiring labels with minimal space, such as patient identification, medication management, and tracking medical equipment and samples, demonstrating their application in small areas.

Using AI-driven scanners enhances reliability and is invaluable in situations where labels may be damaged or contaminated, ensuring seamless data capture even in challenging conditions. The emergence of AI in healthcare can contribute to greater accuracy and quality control from the laboratory to the issuing of medication, providing great opportunities in the industry.

Moreover, healthcare organisations are increasingly embracing RFID & RTLS technology in patient tracking and paving the way for efficient equipment tracking and the diligent monitoring of high-value assets, ensuring every crucial item is accounted for and monitored with total accuracy.

Automotive & Industrial Labels

Durable, chemical-resistant labelling is essential for automotive and industrial workflows. It supports effective parts tracking, safety communication, and precise component traceability. These environments often expose labels to harsh conditions, including heat, abrasion, oils, solvents, and constant handling, making material durability and print resilience critical for ensuring system reliability. Looking ahead to 2026, several key trends are shaping labelling in these sectors:

Increased demand for labels that can withstand extreme heat, oil, and solvents. Automotive operations require labels capable of withstanding exposure to chemicals, coolants, degreasers, lubricants, and high-temperature manufacturing processes. This is especially important for components under the bonnet, engine parts, and assemblies moving through paint shops, machining cells, and metal fabrication lines.

Continued use of Code 39 and Code 128 standards. These industry-trusted symbologies remain the backbone of automotive and industrial identification systems. Code 39 is widely used due to its flexibility and compatibility in manufacturing and defence environments, while Code 128 enables denser encoding for complex workflows where space is limited. Their longevity reflects decades of reliable performance in demanding environments.

Growing adoption of Smart Label technology to support lean manufacturing efficiency. As operations become more digitised, the adoption of RFID, NFC, and IoT-enabled labels is accelerating. These technologies facilitate automated asset management, real-time location tracking, visibility of work in progress, and improved error reduction on the factory floor. Smart labels help organisations reduce waste, optimise inventory control, and strengthen traceability across multi-stage production workflows—key components of modern lean methodologies.

Moreover, many facilities are beginning to integrate AI-driven scanning to compensate for damaged or low-quality labels found in rugged industrial settings. This improves first-time read rates on production lines with fixed AI scanners and ensures continuity, even when labels encounter wear during machining, assembly, and logistics handling.

The evolution of automotive and industrial labeling goes beyond simply achieving greater durability; it focuses on facilitating smarter, faster, and safer workflows. As operations increasingly adopt digital transformation initiatives, a clearly defined labeling strategy becomes essential for ensuring compliance, accuracy, and long-term efficiency throughout the entire supply chain.

Choosing the Right Label: A Modern Checklist

When selecting your label, consider the following points:

- Environment: heat, moisture, chemicals, abrasion

- Regulatory compliance: especially in healthcare, food, and pharmaceuticals

- Data Capture method: mobile, fixed, IoT, RFID readers

- Data needs: track & trace, consumer engagement, compliance

- Print technology: Traditional Barcode labels printing vs Smart Label encoding

- Automation readiness: integration with ERP, IoT or warehouse systems

Looking Ahead: Total Labelling Solutions for the Modern Business

As labelling technology continues to evolve—integrating AI, smart sensors, symbology evolution, and digital transformation—choosing the right label has never been more essential. From durable automotive labels and high‑accuracy healthcare solutions to smart RFID/NFC options and specialist materials, GSM Barcoding can support every element of your labelling strategy. Speak to one of our advisors today for a sample, a quote or expert advice on labels.