When starting small, it’s reasonable to think that keeping track of your stock can be done with a simple pen and paper or keeping records in spreadsheets. A monthly audit or tracking ins and outs is straight forward when you’re a small business, but what happens as you grow?

It’s no longer manageable, higher turnover of stock, extended product lines and variants, short-term promotions and a number of stock locations where inventory can be misplaced adds to the complexity of knowing what stock is in hand and where.

As they say, “knowledge is power” and the better knowledge and visibility that managers have over their stock they can not only make informed choices regarding working capital tied up in stock, turnover and slow-moving lines and wastage but also about how they will respond to customers’ demands – now and in the future.

As a small business, there are a number of demands and pressures and finding the time to re-assess your stock control system may not be at the top of your priority list. That’s understandable, but think for a second on how many problems a barcode stock control system will solve, including:

- Knowing how much stock you have

- Knowing the location of your stock

- Enabling quick and accurate stock takes

- Keeping customers informed on stock and delivery

For small and growing businesses, reducing costs tied up in stock, speeding up processing of orders and improving customer service are benefits that will directly affect the bottom line and allow you to compete more effectively. So, what is stopping SME’s making this transition?

Fear, cost, complexity and time are some of the concerns that businesses have when considering introducing a barcoded warehouse management system. The good news is that if you are one of the millions of SMEs, Barcoding makes a great barcode system for a small business. With Barcoding, you can turn your manual processes into a fully functioning warehouse management system with a simple barcoding system. No duplication of existing systems or double keying of data, no complex and expensive IT projects, and no endless system integration meetings.

How Does it Work?

A barcode warehouse management system such as G-Smart Stock is, a standalone system. Sitting between your warehouse and management team, it adds barcode tracking functionality to your existing system. The software combination becomes the hub for your business data, with your database handling the transactions and order processing and the stock control managing the stock tracking and movements.

The barcode solution works with the existing product codes and barcodes held in in your system, eliminating the need for re-keying of any data that is already in your system. Your product and sales/purchase order data arrives seamlessly into the software and when stock movements are made, they are again seamlessly updated. This approach enables SME’s to quickly and cost-effectively add warehouse barcoding to the business whilst eliminating complex set up and integration.

What Features Does A Barcode Warehouse Management System Add-On Bring to Warehouses?

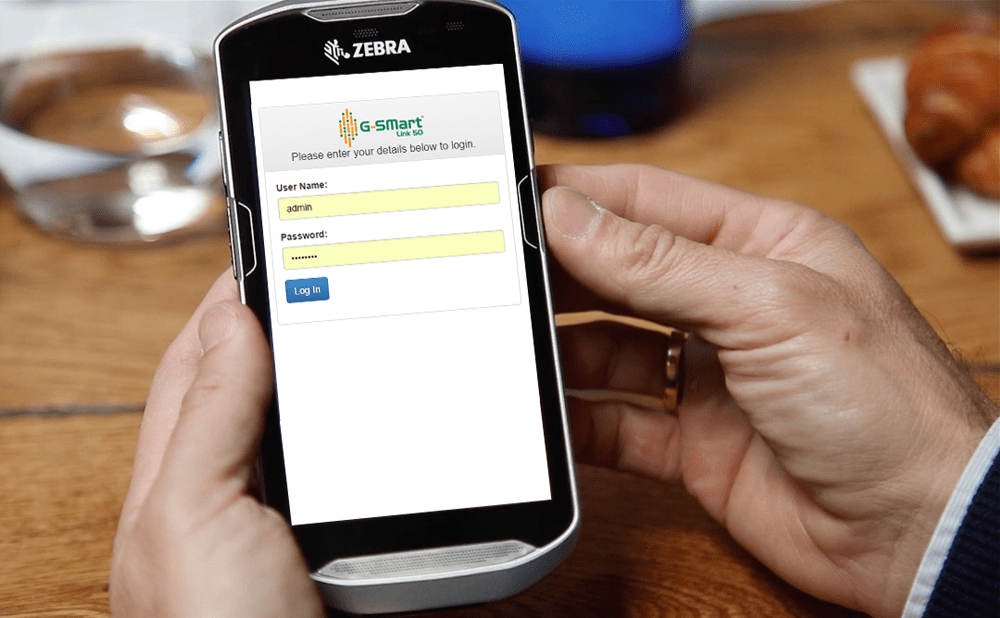

Once the software is installed on your local server, your business will be able to barcode your stock, storage locations and keep track of stock movements and run audits using mobile handheld computer and compatible devices that connect live and wireless to the system.

With built in label creation tools, you can print labels for the shelf edge locations and for existing and received stock items. It is simple and intuitive, the barcodes held in the add-in software and imported from the barcode field can be printed, eliminating re-typing.

For warehouse workers managing goods-in, put-away, goods-out and stock counts, they can access live information on wireless mobile computers, which speeds up finding the location of stock and processing of orders whilst facilitating communication. Purchase orders and sales orders automatically appear on the mobile computers and when conducting the goods-in and goods-out processing, the system validates against the orders ensuring that no mistakes can be made.

-

Alternative & Supplier barcode integration

– Allows you to store additional alternative barcodes i.e. supplier barcodes for each product and cross reference with sage barcodes.

-

Box quantity barcodes

– For barcoding and tracking box containers or pallets that contain other barcoded boxes.

-

Quarantine locations

– For staging areas and returns that require temporary holding until the warehouse team can put-away or allocate.

-

Managing and tracking stock held externally

– Track stock held by sales reps, engineers or third parties.

In some instances where the business needs advanced tracking options or where the business requires unique features, there are a number of modules available that can be added to the barcode software. The stock control solution from GSM Barcoding provides a number of optional modules including:

Stock Control Batch Tracking

Where businesses produce stock items in batches such as chemicals or pharmaceuticals adding a batch module to the software, enabling the tracking of the batch reference against the individual items, enabling improved quality control and traceability. If there is an issue with an individual product, batch tracking facilitates investigations and even recall of associated items.

Stock Control Serial Tracking

Keep track of individual items movements and history by adding the serial tracking module to your software. Serial tracking is fundamental for operations who are typically offering warranties on items such as TV’s or laptops, where there is a legal warranty and quality control reason for being able to control warranties. A necessary compliance in many industries, the serialisation of stock automates the tracking process and facilitates recall if necessary.

Bill of Materials (BOM) Tracking

Does your business assemble products or bundle items for sale? If so, then integrating a Bill of materials (BOM) module into your system will allow you to barcode each component and track into an assembled finished product. BOM tracking in G-Smart Stock facilitates stock control for SME’s assembling components into products for sale, enabling stock control over the production process.

Implementing Barcode Stock Control

As previously stated, taking the leap and transforming your accounts system into a barcode warehouse management system may seem like a scary challenge, but the benefits in productivity, accuracy and management visibility means it will pay back in no time at all.

Start off with familiarising yourself with some of the features and ask yourself what you really want from the warehouse software. Do you need to manage stock in multiple locations? Does your stock require serial tracking? How many operatives require software licenses?

These are just a few of the most basic questions. To really understand your requirements, speak to a systems consultant that can discuss your requirements and the best solution for you. Ask your consultant to show you the product features and capabilities, a free walk-through demo is the best way to really get an understanding of how your business will be able to use the barcoding add-on software to its full capabilities.

Once you have been through the live demo of the software you should have an understanding of the capabilities and features but also the consultant will provide you with an opportunity to ask any questions you may have and provide you with information on how to move your project forward.